TECHNOLOGICAL INNOVATION

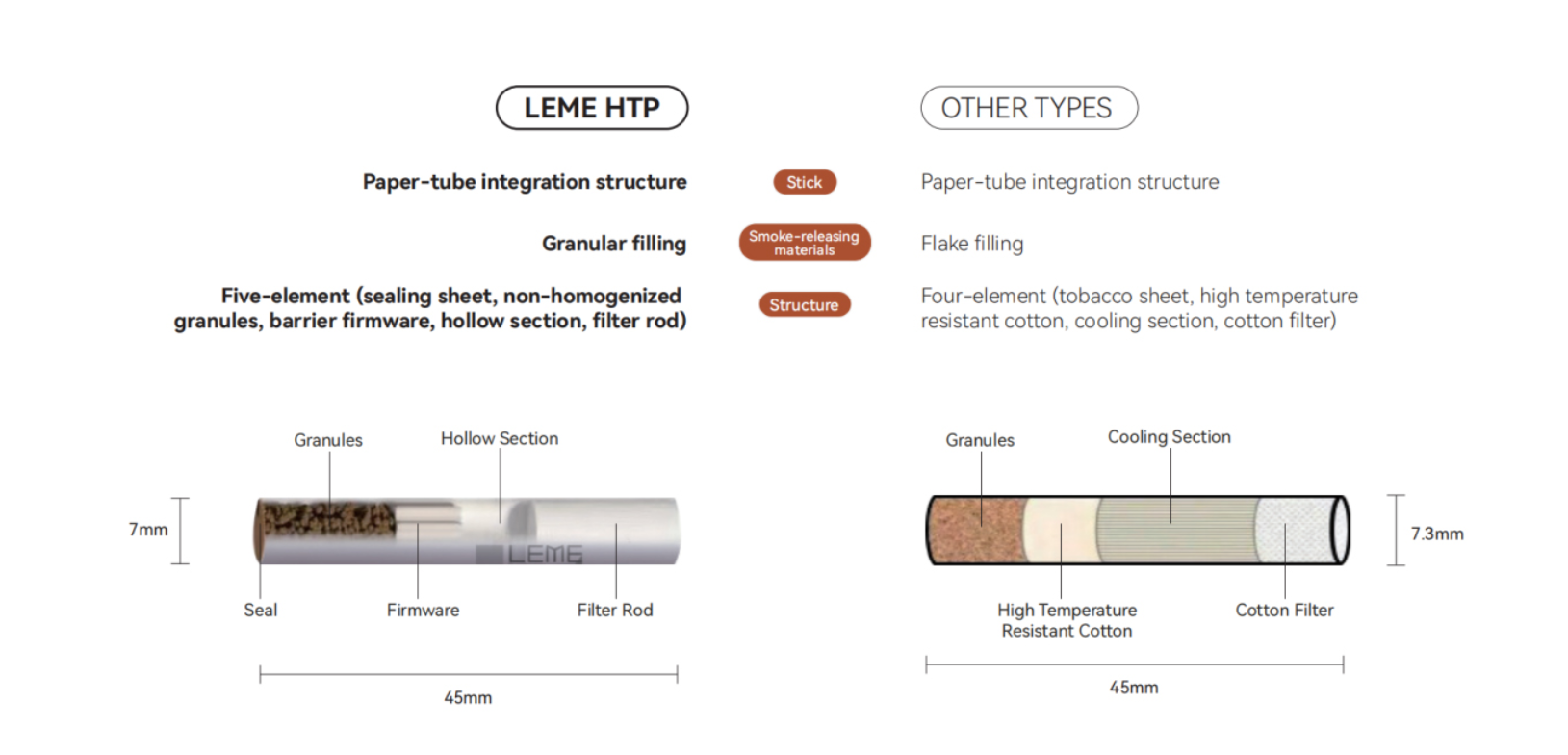

Stick Structure Comparison

LEME holds its patent for heated tobacco structure, LEME is the first company to apply for the "granular five-element stick structure" as the core invention patent.

The five-element structure refers to the sealing sheet, the non-homogenized granules, the barrier firmware, the hollow section, and the filter rod. Compared with other sticks, LEME has a unique stick structure:

Unique and Innovative Technology of Granulation

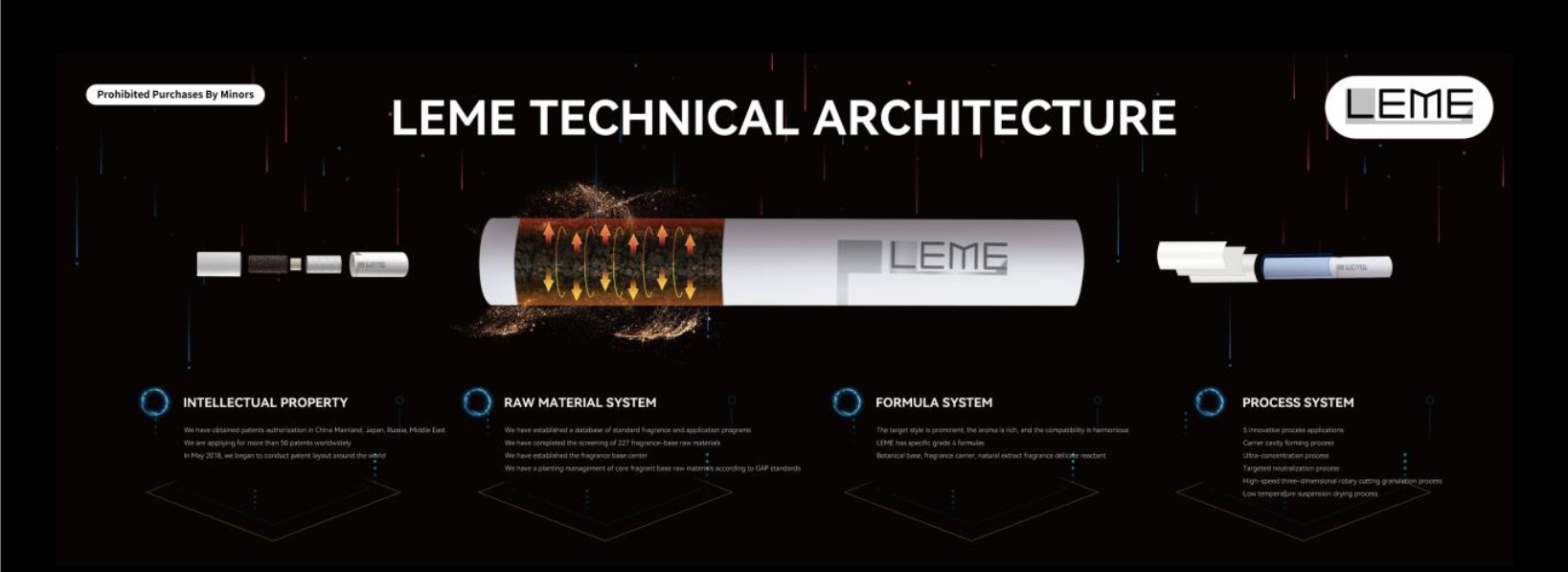

LEME adopts 5 innovative process applications: carrier cavity forming process, ultra-concentration process, targeted neutralization process, high-speed three-dimensional rotary cutting granulation process, low-temperature suspension drying process. Existing granulation methods mainly include blending granulation, extrusion granulation, spray-drying granulation, pressure-drying granulation, dispersed mist granulation, hot melt forming granulation, etc..The technology of all methods is divided into two parts: granule formation and drying. The selection of technology for both stages affects the quality of the granules. At present, the commercially available granulation equipment is mature in the pharmaceutical industry, and the equipment parameters are not suitable for the preparation of heat-not-burn smoke-releasing granules.

According to the characteristics of the product formula, LEME has customized two pieces of granulation equipment suitable for heat-not-burn smoke-releasing granules, a 25L experimental granulator and a 200L production granulator, the granules do not have to go through these steps, such as extrusion, spheronization, etc., it can be formed once in the blending process, and the granules are uniform. At the same time, a low-temperature boiling drying line has been customized recently, which can minimize the loss of aroma during the drying process.

Mature and Diversified Formula System

The target style is prominent, the aroma is rich, and the compatibility is harmonious. LEME has specific grade 4 formulas: botanical base, fragrance carrier, naturally extracted fragrance, and delicate reactants.

Strictly Standardized Raw Materials Screening System

The selection of base materials is the most critical factor affecting the taste of the product, and the blending is only the embellishment and assistance. LEME has built a database of standard fragrance and application programs and screened out 227 fragrance-based raw materials. At the same time, LEME has set up its fragrance-based center and managed the planting of core fragrance-based raw materials according to GAP standards.

In terms of product taste, LEME insists on outstanding style, rich aroma, and harmonious compatibility as a goal, takes the key technology of combustion pyrolysis as a bridge, based on four core blocks, such as the plant pyrolysis materials to enhance the smoke sensation, the natural extract materials to improve the sensory comfort, the characteristic reaction materials to enhance the quality of aroma and the basic solvent formulation to improve the concentration of aerosol granules, resulting in a flavor formulation system with characteristic style. LEME Heated Tobacco Products have been unanimously recognized by the domestic and foreign markets.

Quality Control

LEME factory strictly implements dust-free production, and sticks implement strict QC standards during the whole process from granulation - filling - sticks forming - labeling - packaging - product forming. All sticks and finished products are currently subject to a full inspection.

In particular, for new flavors and flavor upgrades, the company organizes personnel and consumers to carry out a synchronously strict evaluation. At the same time, the company also regularly organizes personnel to conduct random inspections of product quality and sensory quality to ensure product quality safety and consistency to the greatest extent.

A Better Heated Tobacco Product

LEME created its unique heated tobacco product with its innovative technology! Firstly, the total amount of lignin, pectin, and proteins in the matrix has been reduced by 40%; the usage of PG and VG decreased by 35% compared with the previous generation, and then the granule’s weight is 1.5 times that of the average of similar products, and the number of effective puffs hits up to 16; finally, the total amount of granule matter in the smoke is 1.6 times that of the 1.0 generation product, strong smoke, and mellow aroma.